Line Orifices

The line orifice from Stainless Products provides a 3-A sanitary and fully-drainable means of adjusting your process flow rate, balancing backflow, equalizing pressure, and recovering more of your valuable product.

In a hygienic processing system, when product reaches the orifice plate, it’s forced through the hole and converges. As the fluid converges, the pressure and velocity change - increased velocity means a decreased pressure. This reduction in pressure can be useful for a variety of purposes.

Applications

For pharmaceutical and biotech applications we offer heat traceability. 20Ra ID (SF1) and 15Ra EP ID (SF4).

Clean-In-Place (CIP) applications where the pressure is necessary to create the turbulence required for cleaning.

Check excess flow from the system header

Decrease the pressure to a piece of equipment that may not handle the full system pressure.

Provide the required backflow to prevent the pump from causing cavitation, starvation, and pump motor overload and kick out.

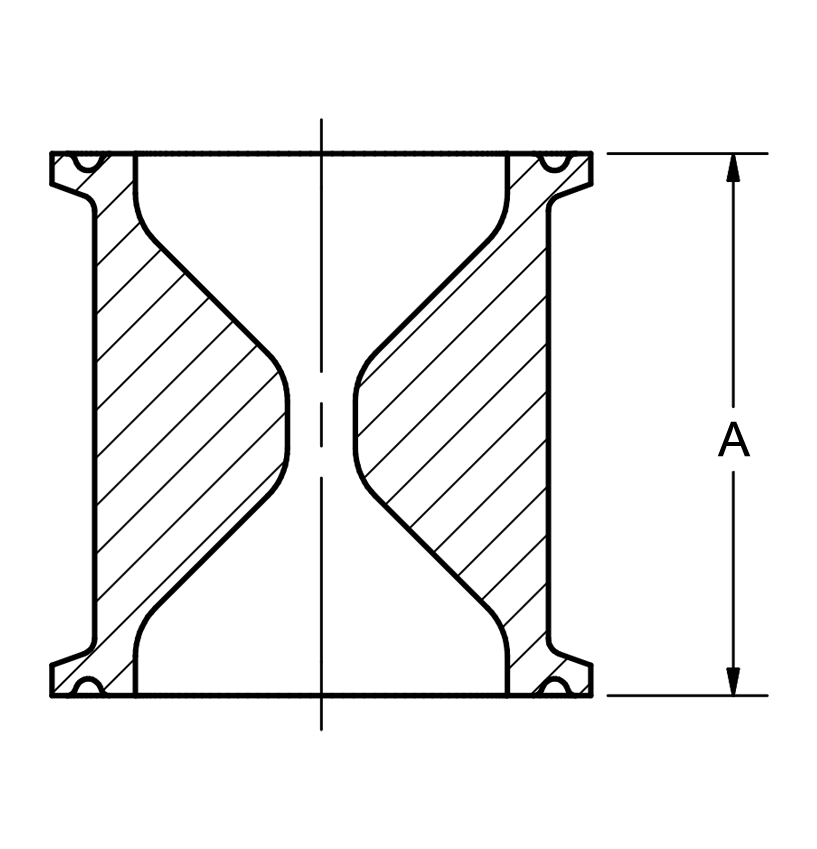

Line Orifice - SP484

The SP484 fixed flow orifice is made to order, and our in-house machining and polishing capabilities allow us to deliver with quality surface finishes (20 Ra is standard).

Looking for a custom size, different connection type, or better surface finish? No Problem! Our state-of-the-art manufacturing capabilities provide quick turnaround and competitive value for custom parts. Contact us today.

| Size | 1/2 | 3/4 | 1 | 1.5 | 2 | 2.5 | 3 | 4 |

|---|---|---|---|---|---|---|---|---|

| A (in) | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 |

All bore sizes made to order.

See the fittings catalog for our full selection of stainless steel fittings. Don’t see what you’re looking for? Contact us for additional sizes.