Sight Glasses

Tri-clamp® inline and cross sight glasses allow you to view product along tank connections, drains, or hoses allowing for the tracking of color and consistency when transferring product. Tank sight glasses offer the ability to view product within a tank without exposing it to the outside elements.

This allows for fermentation or other processes to be monitored visually in the midst of operation. These sight glasses are often installed as a semi-permanent fixture on a variety of tanks. Each sight glass from Stainless Products is 3-A certified and can be disassembled for easy inspection.

Standard Features

Tri-Clamp® end connections

3-A certified

Max temp 200°F

Options available upon request

Acrylic viewport

MTR’s

SP56

Full 360° view of process media. Suited for vertical and horizontal mounting. When mounting in a horizontal position no mechanical force should be exerted on the glass.

| Size | A (3 in. Glass) | A (6 in. Glass) |

|---|---|---|

| 1.5 | 6.50 | 9.50 |

| 2.0 | 6.50 | 9.50 |

| 2.5 | 6.50 | 9.50 |

| 3.0 | 6.50 | 9.50 |

Operating Pressure: Borosilicate 100 PSI / Acrylic 150 PSI. *

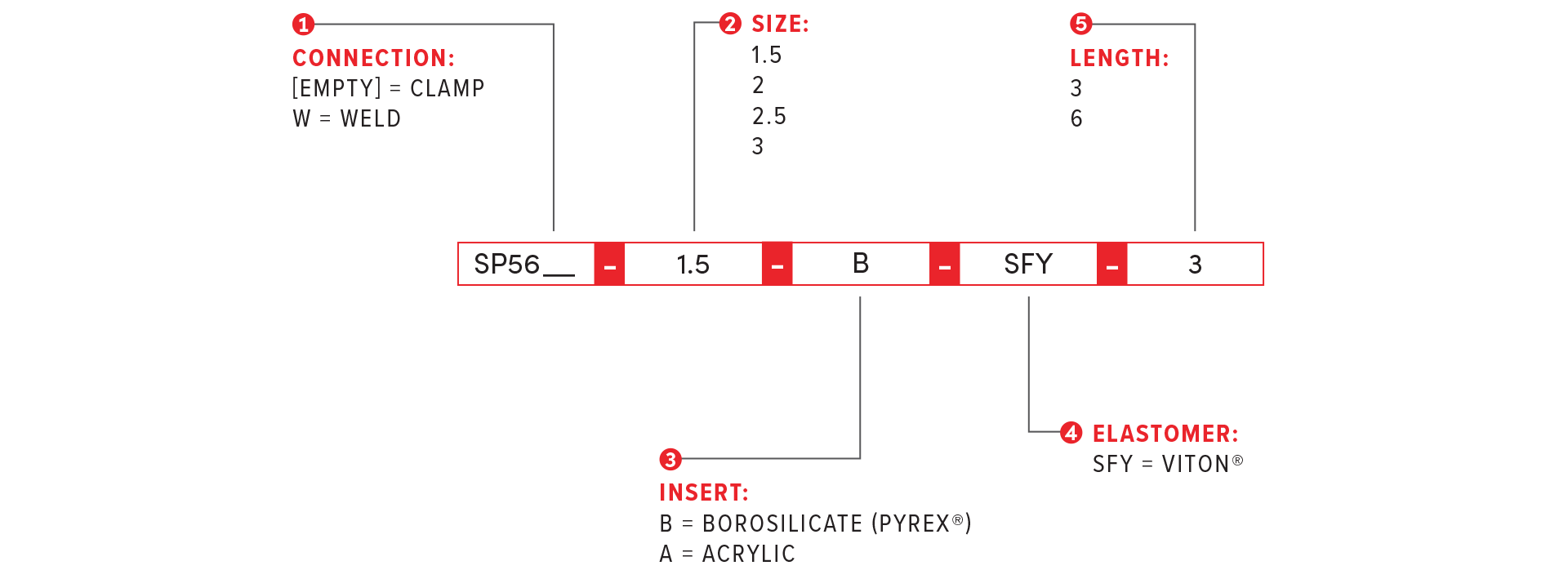

Part Number Configurator

SP54

Cross style sight glass provides a view inside of the production flow.

| Size | A (in) | B (in) |

|---|---|---|

| 1.5 | 4.50 | 5.50 |

| 2.0 | 4.75 | 7.00 |

| 2.5 | 5.25 | 7.00 |

| 3.0 | 5.75 | 7.50 |

| 4.0 | 7.25 | 9.00 |

Operating Pressure: Borosilicate 150 PSI / Acrylic 150 PSI. *

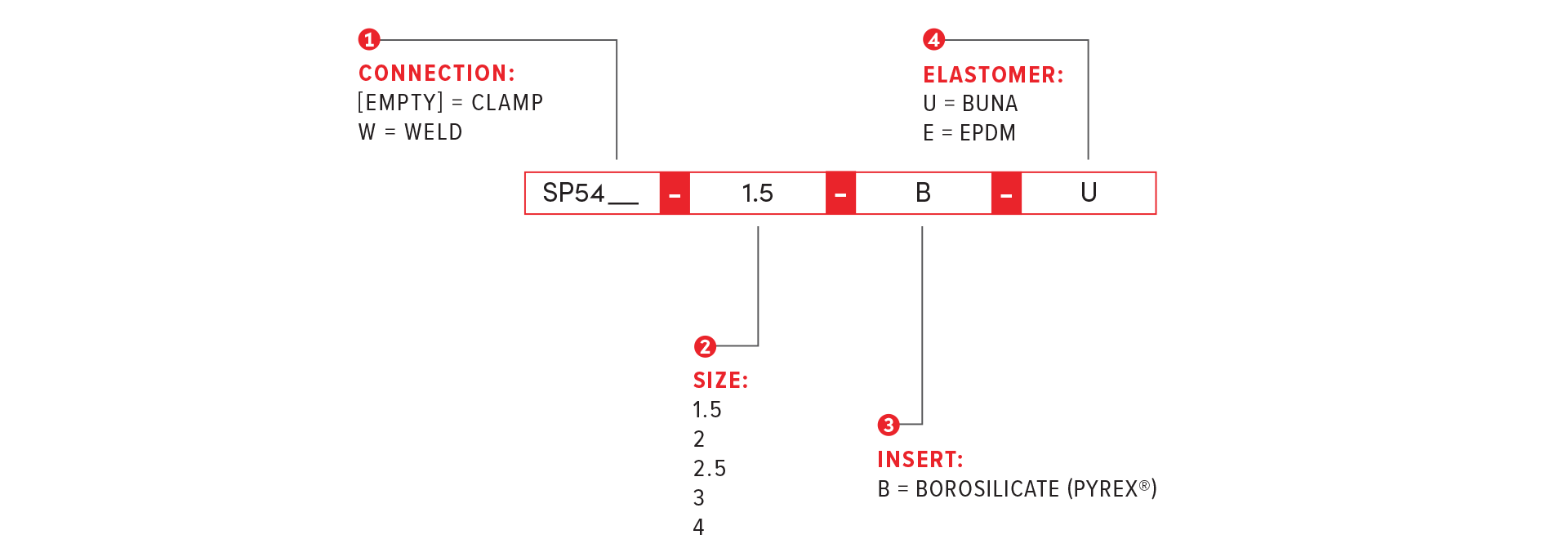

Part Number Configurator

SP54SW

Compact unit with easy disassembly. Commonly used in vessels.

| Size | A (in) |

|---|---|

| 1.5 | 1.25 |

| 2 | 1.25 |

| 2.5 | 1.25 |

| 3.0 | 1.25 |

| 4.0 | 1.50 |

Operating Pressure: Borosilicate 150 PSI / Acrylic 150 PSI. *

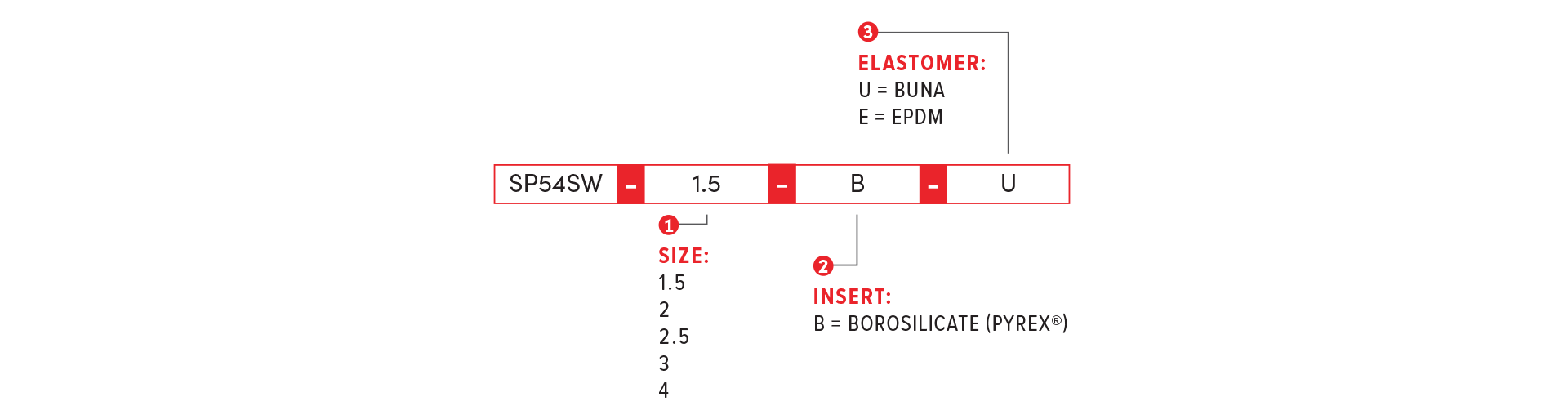

Part Number Configurator

* Sudden pressure spikes due to water hammer or similar events can cause failure or rupture of sight glasses. Sudden changes in temperature are known to cause failures in borosilicate materials, especially when going from hot to cold. Operating pressures were determined after testing at ambient temperatures. Increased temperatures can cause leakage or rupture below operating pressure.